international standard industrial furnace manufacturer

- Last Up To 10 Years

- Energy Saving and Low Cost Investment

- Stable & Evenly Distributed Heat

More Than 10 Years

as industrial furnace manufacturer and service in indonesia

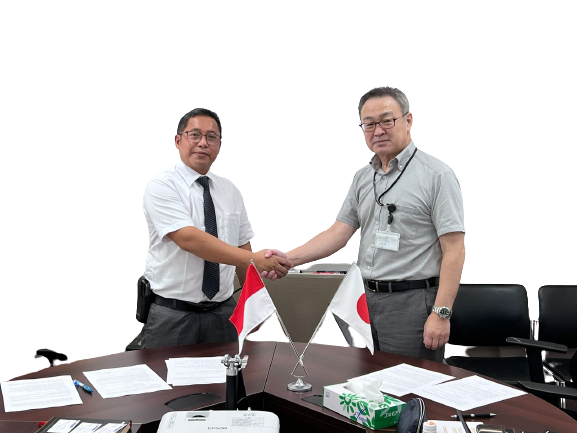

As a leading industrial furnace manufacturer in Indonesia, our commitment is to provide the highest quality furnace products that meet international standards. We have a proven track record of supplying our furnace products across various regions of the country and even to foreign destinations like Japan and beyond.

Our team of professional staff is ready to assist you with everything from consultation on specifications to after-sales service and always prioritizing customer satisfaction. With the strong reputation we have built over the years in the industry, we continue to solidify our position as the top-quality furnace manufacturer in Indonesia.

our featured product

OTHER PRODUCTS

Bricketing Machine

Waste Gas Recuperators

Ladle Transfer and Ladle Preheating

Crucible Furnance and Crucible Sales

Holding Furnance With Immersion Heater

Refractory Furnance

Anneling, Tempering dan Normalizing Furnance

Burner System

For your product needs, you can contact us

To request specifications or other product catalogs, please fill out the form below.

OUR PROJECT PORTFOLIO

OUT PARTNERS

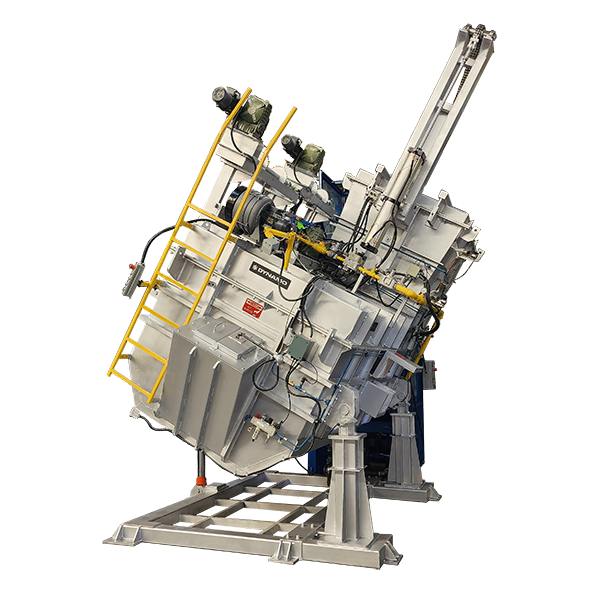

TIMITRA IP collaborates with leading furnance makers from Canada to improve quality and technology in the field of melting furnaces.

These partnerships result in innovation and new standards in the industry

These partnerships result in innovation and new standards in the industry

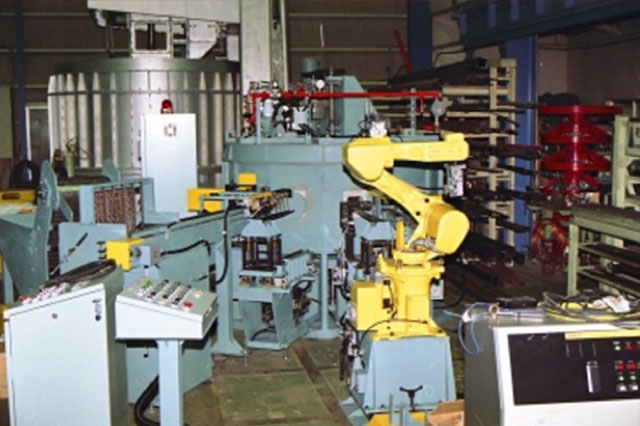

To improve quality and technology in the field of Heattreatment Furnance, TIMITRA IP cooperates with furnance makers from Japan, whose superior product is the Rotary Heattreatment Furnance, and can also provide flow forming machines.

Metalpress 500 EVO Briquetting Press

Metalpress Metal Briquetting Presses

To meet industrial needs in the field of processing Aluminum Chips, we also work with bricketing machine makers from Turkey, whose products are high-tech, environmentally friendly and cost competitive

EASTERN Recuperators Product

Suitable for Melting, Holding & Tilting Furnaces

Along with saving energy from aluminum furnishings, industrial steel furnishings and other furnishings, we partner with EASTERN Recuperators. With a recuperator, the remaining hot air or exhaust gas can be reused for fuel so that it can reduce production costs by 15% of the energy used

Dynamo

Furnance

Furnance

juko

Furnance

Furnance

comafer

macchine

macchine

eastern

recuperator

recuperator

OUR CLIENTS ARE OUR SUCCESS STORIES

100+ domestic and international companies trust and use solutions from PT TIP, making us their go-to choice for their project needs. Consult with our specialist team for your project requirements.